In the competitive landscape of thermal insulation, industry professionals increasingly face a critical decision: stick with traditional foam solutions or adopt next-gen vacuum insulation technology. At the forefront of this revolution stands vacuglass – a vacuum insulated glass innovation redefining performance benchmarks. Let’s analyze how this cutting-edge material outperforms conventional foam insulation across four decisive factors.

While foam insulation (R-3.5 to R-6 per inch) remains popular in construction, vacuglass shatters thermal limitations with its ultra-low U-values (0.4-0.6 W/m²K). This translates to:

50% greater heat transfer reduction vs. premium foam

R-values surpassing 10 per inch in practical applications

Stable performance regardless of external humidity

The secret lies in vacuglass's vacuum-sealed microstructure – eliminating convective heat loss that plagues even closed-cell foams.

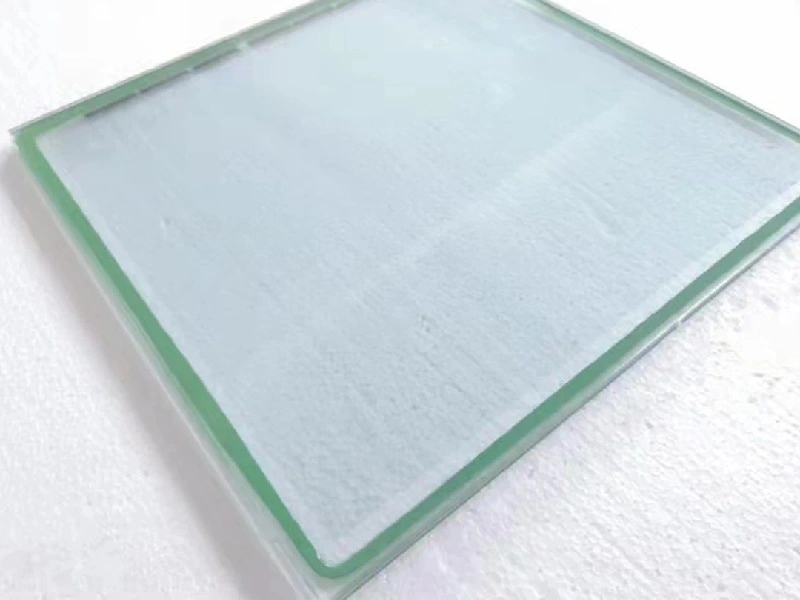

Foam’s bulkiness often compromises design integrity, requiring thick installations for adequate insulation. Vacuglass innovates with:

Slim 6-12mm profiles enabling invisible integration

Structural versatility for curved surfaces and retrofits

Dual functionality as both insulator and transparent barrier

This makes vacuglass ideal for modern architectural challenges like energy-efficient skyscrapers and historic building preservation.

Field studies reveal foam's vulnerabilities:

Up to 20% R-value loss from moisture absorption

Chemical breakdown in UV-exposed applications

Frequent need for replacement layers

Vacuglass counters with:

Hermetic seals maintaining vacuum integrity for 25+ years

UV-resistant borosilicate glass layers

Zero off-gassing or material degradation

While foam production often involves environmentally harmful blowing agents, vacuglass:

Utilizes 80% recycled glass content

Reduces building energy consumption by 30-40%

Achieves full recyclability through modular construction

Though foam retains niche applications in temporary structures, vacuglass delivers unmatched:

Thermal efficiency for net-zero buildings

Design freedom for visionary architects

Lifecycle cost savings through maintenance reduction

The evergreen glass leads this insulation revolution with patented vacuglass solutions. Our ISO-certified manufacturing process ensures:

Custom panel sizing (up to 3m x 1.5m)

Fire-rated variants for commercial use

15-year performance warranties