Heat-soaking is a process used to help reduce the incidence of spontaneous breakage due to rare nickel-sulfide (NiS) inclusions or fabrication damage in tempered glass before it reaches the field. It involves placing tempered glass inside a chamber and raising the temperature to approximately 550 degrees to accelerate nickel-sulfide expansion and cause the glass to break in the heat-soak chamber, thus reducing the risk of potential breakage in the field.

Most experts agree that heat-soaking does not guarantee 100 percent elimination of potential spontaneous breakage. Further, the process may create other risks. Please see TD-138 for a more complete discussion of the topic. This process is often performed by specialized heat treated glass suppliers who provide custom architectural glass for various construction and design applications.

| Feature | Heat Soaked Glass | Regular Tempered Glass |

| Risk of Spontaneous Breakage | Minimized | Possible |

| Safety | Enhanced | Lower |

| Quality Control | Improved | Standard |

| Building Code Compliance | May be Required | Not Required (usually) |

| Durability | Increased (due to reduced breakage risk) | Standard |

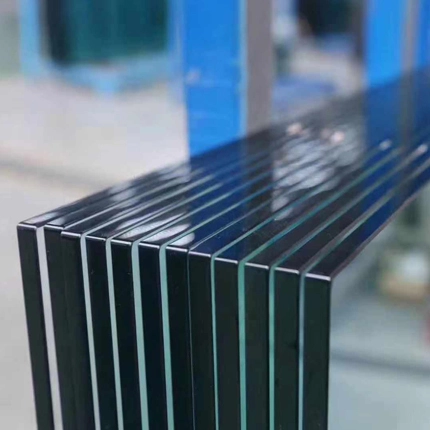

Glass Thickness | 2mm - 2.5mm - 3mm - 4-5mm - 6mm - 8mm; 10 mm - 12mm - 15mm - 19mm - 22mm - 25mm |

Glass Color | Clear, blue, bronze, green, gray, tinted reflective, ultra clear, online/offline lowe etc; |

Min size | 50x50mm; |

Max size | 3300x8000mm; |

Shape in | Flat, curved, double or various curved; |

Reduced Risk of Spontaneous Breakage:

The primary benefit of heat soaked glass is its significantly minimized chance of spontaneous breakage.

Regular tempered glass can contain nickel sulfide (NiS) inclusions, which can weaken the glass over time and lead to unexpected shattering.

The heat soak process identifies and exposes these inclusions by subjecting the glass to high temperatures for several hours.

Any glass containing NiS inclusions will typically fracture during this process, eliminating the risk of future breakage.

Enhanced Safety:

By removing the possibility of spontaneous breakage, heat soaked glass offers a significant safety improvement.

This is crucial in applications where falling glass could cause injuries, such as overhead glazing, partitions, and shower enclosures.

Thermal Stress: The heat soaking process induces thermal stress within the glass, causing any nickel sulfide inclusions to undergo a phase change. If a nickel sulfide inclusion is present, it may expand during this phase change, leading to a fracture within the glass. The goal of heat soaking is to identify and eliminate tempered glass panels with potential nickel sulfide inclusions before they are installed.

Reduced Risk of Spontaneous Breakage: By subjecting tempered glass to heat soaking, the risk of spontaneous breakage due to nickel sulfide inclusions is significantly reduced. Glass panels that contain such inclusions are more likely to fracture during the heat soaking process, allowing them to be identified and removed from production.

Quality Assurance: Heat soaking serves as a quality assurance measure to enhance the reliability and safety of tempered glass products. It helps identify and eliminate defective glass panels before they are installed in buildings or other applications where spontaneous breakage could pose a risk to safety.

Pls contact us if you have any inquire or questions, thank you.

No.12111, JINGSHI ROAD, LIXIA DIST, JINAN CITY, SHANDONG PROVINCE, CHINA