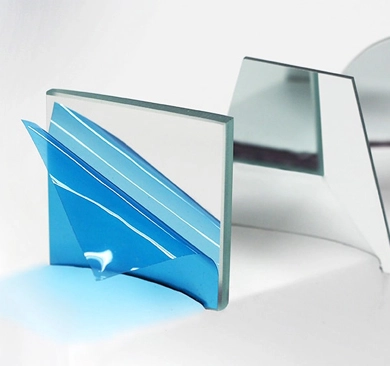

A front surface mirror, also known as a front surface mirror or front-coated mirror, is optical mirror with a reflective coating applied directly to the front surface of the glass.In classic mirrors, the reflective coating is usually put to the back surface of the glass, resulting in a twofold reflection as light passes through it before being reflected back. Front surface mirrors prevent secondary reflections, resulting in a cleaner and more accurate reflection. These specialized mirrors are often detailed in a mirror manual and can be considered a type of custom architectural glass. They are typically produced in a decorative glass factory that specializes in high-precision optical components. These mirrors are highly sought after by front surface mirror manufacturers like us for their precision and clarity in applications like laser systems, scientific instruments, and kaleidoscopes.

Contact us now for front surface mirrors for sale!

Standard Thk | 1.10mm +/-0.1mm; |

Optical Reflection | Ravg > 98 % @ 420–680 nm, i = 45°; Highly reflective up to 12 μm |

Coatiing | Optical grade silver coating protected by overcoating |

Surface quality | Typ. 60-40 scratch & dig (MIL-0-13830A) |

Adherence according to MIL-M-13508C, 4.4.6, Tape Test | |

Hardness according to MIL-M-13508C, 4.4.5, 50 x | |

1. Single Reflection: The main advantage of front surface mirrors is that they eliminate the double reflection caused by light passing through the glass before being reflected. This makes them ideal for applications where precision and accuracy in reflection are crucial.

2. Optical Clarity: Since there is no double reflection, front surface mirrors provide improved optical clarity compared to conventional mirrors. This is particularly important in applications such as optical instruments, scientific equipment, and imaging systems.

3. Coating Types: Various reflective coatings can be applied to the front surface, including aluminum, silver, or other metallic coatings. The choice of coating depends on factors such as reflectivity, durability, and specific application requirements.

4. Applications in Optics: In optical instruments, telescopes, microscopes, and other devices where accuracy and minimal distortion are essential.

5. Projection Systems: In projection systems, including overhead projectors and video projectors, where maintaining image quality and sharpness is important.

6. Dental and Medical Instruments: In dental and medical instruments, such as dental mirrors and endoscopes, where clear and accurate reflection is critical for diagnostics and procedures.

7. Entertainment and Display: In the entertainment industry, including stage performances and magic shows, to achieve specific optical effects without distortions.

8. Television and Display Technologies: In certain display technologies, front surface mirrors may be used to enhance image quality and reduce glare.

It's important to note that front surface mirrors are more delicate than traditional mirrors because the reflective coating is exposed on the outer surface. Care must be taken during cleaning and handling to avoid scratching or damaging the reflective coating. Additionally, the choice of coating material depends on the intended use, with silver coatings often used for applications requiring high reflectivity in the visible spectrum.

Pls contact us if you have any inquire or questions, thank you.

No.12111, JINGSHI ROAD, LIXIA DIST, JINAN CITY, SHANDONG PROVINCE, CHINA