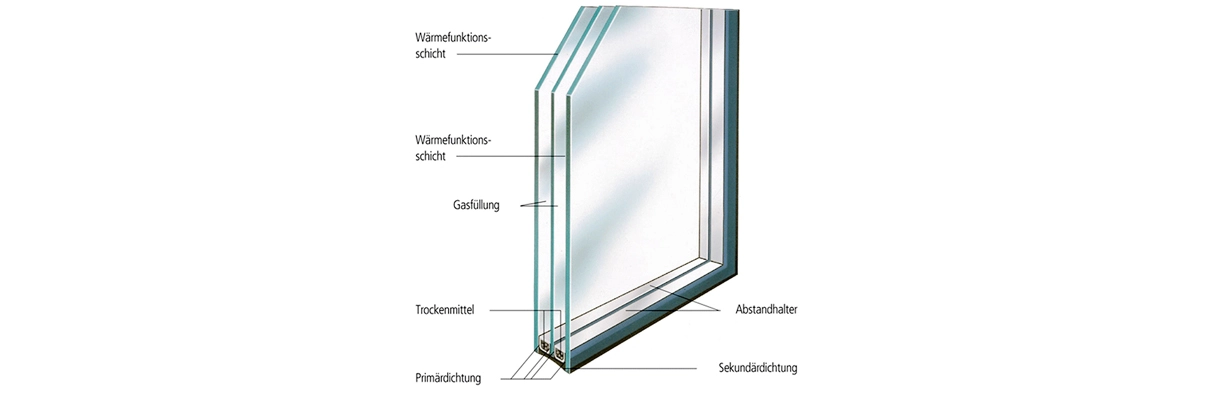

Insulated glass (IG), also known as double glazing or triple glazing, is a type of glass that is made up of two or more panes of glass that are separated by a spacer. The spacer is filled with a gas, such as argon or krypton, or a vacuum. The gas or vacuum helps to insulate the glass, which can reduce heat loss in the winter and heat gain in the summer.

IG units are available in a variety of styles and configurations. You can choose from a variety of spacer materials, glass types, and frame colors. IG units can be used in new construction or renovation projects.

IG units are a good choice for homes and buildings that are located in areas with extreme weather conditions. IG units can help to reduce energy costs and improve the comfort of your home or building.

Cutting and Cleaning

Cutting: The process begins with cutting the glass sheets to the required sizes based on specific orders or standard dimensions. This is usually done with high precision cutting tools to ensure clean edges.

Cleaning: After cutting, the glass sheets are thoroughly cleaned to remove any impurities, dust, or residues. This step is crucial to prevent any defects or blemishes between the glass panes.

Spacer Assembly

A spacer is placed around the perimeter of one of the glass sheets to create the gap between the panes. Spacers are typically made of metal or composite materials and contain a desiccant that absorbs moisture within the cavity to prevent condensation.

Sealing

The perimeter of the unit is then sealed with a high-grade sealant, often silicone or butyl-based, to prevent air and moisture from entering the space between the glass panes. In some cases, a secondary sealant is applied for enhanced durability and insulation.

Quality Inspection

Each IGU undergoes a thorough quality inspection to check for any defects, such as scratches, impurities, or sealant failures. The units are also tested for their hermetic seal to ensure no gas leakage for gas-filled units.

Packaging and Shipping

Once approved, the insulated glass units are carefully packaged to prevent damage during transportation and then shipped to their destination for installation.

For the insulated glass the main purpose is for evergy saving, especially using lowe as a part of the glass unit. However, when we use the insulated glass in skyscraper the safety features should be take into consideration. So we will do some process for this purpose by:

1. Use ultra clear glass in replace of the clear glass;

2. Use Heat strengthened glass in replace of the tempered glass or heat soaked test;

3. Use tempered laminated in replace of the monolithic tempered glass;

After those, the insulated glass will much more safe and energy saving.

Pls contact us if you have any inquire or questions, thank you.

No.12111, JINGSHI ROAD, LIXIA DIST, JINAN CITY, SHANDONG PROVINCE, CHINA